In the rapidly developing modern industry, reducing labor intensity and improving production efficiency are one of the goals pursued by enterprises. In this context, PMCC permanent magnetic chuck has become a powerful tool to reduce labor intensity with its unique working principle and significant advantages.

The traditional way of fixing workpieces often requires manual tightening and loosening operations, which is not only labor-intensive but also inefficient. However, the PMCC permanent magnetic chuck realizes rapid adsorption and release of the workpiece by turning on and off the electromagnetic coil, thus greatly reducing labor intensity.

Specifically, when the electromagnetic coil is energized, the PMCC permanent magnetic chuck will generate strong adsorption force to firmly fix the workpiece on the surface of the chuck. When it is necessary to release the workpiece, just cut off the power supply, the electromagnetic coil is powered off, the adsorption force disappears quickly, and the workpiece can be easily removed.

Improve work efficiency: By reducing labor intensity, workers can perform their work more easily, thereby improving work efficiency. After using the PMCC permanent magnetic chuck, workers no longer need to work hard to tighten and loosen the workpiece, and can devote more energy to the processing process and improve production efficiency.

Reduce human errors: Manual operations often involve errors and uncertainties, and the fast and accurate adsorption and release functions of the PMCC permanent magnetic chuck can reduce the occurrence of human errors. This helps improve product quality and processing accuracy and reduce scrap rates.

Improve the working environment: Reducing labor intensity can not only reduce the physical burden on workers, but also improve the working environment. Workers no longer need to perform repetitive high-intensity operations for a long time and can work more comfortably, improving job satisfaction and happiness.

In practical applications, PMCC permanent magnetic chucks have successfully reduced the labor intensity of many enterprises. For example, in the automobile manufacturing industry, PMCC permanent magnetic chucks are widely used in body welding, stamping and other processes. By quickly and accurately fixing workpieces, they reduce workers' labor intensity and improve production efficiency. At the same time, PMCC permanent magnetic chucks also play an important role in metal processing, machinery manufacturing and other fields, bringing significant benefits to enterprises.

PMCC permanent magnetic chuck, with its unique working principle and significant advantages, plays an important role in reducing labor intensity and improving industrial efficiency. With the continuous advancement of technology and the expansion of market demand, PMCC permanent magnetic chucks will be applied and developed in more fields.

- Home

- About Us

- Product

- PMSC Super permanent magnetic chuck

- PML Permanent magnet lifter

- PTK Vacuum chuck

- PTM Electric permanent magnetic chuck

- PTSM Injection molding machine rapid die change

- PMCC Permanent magnetic chuck

- Magnetic base

- PMC Magnetic drum sewage processor

- PML Tapping machine suction cup base

- ETM Electric tapping machine

- Drill sharpeners

- Milling cutter sharpeners

- Tapping and grinding machines

- Magnetic rods

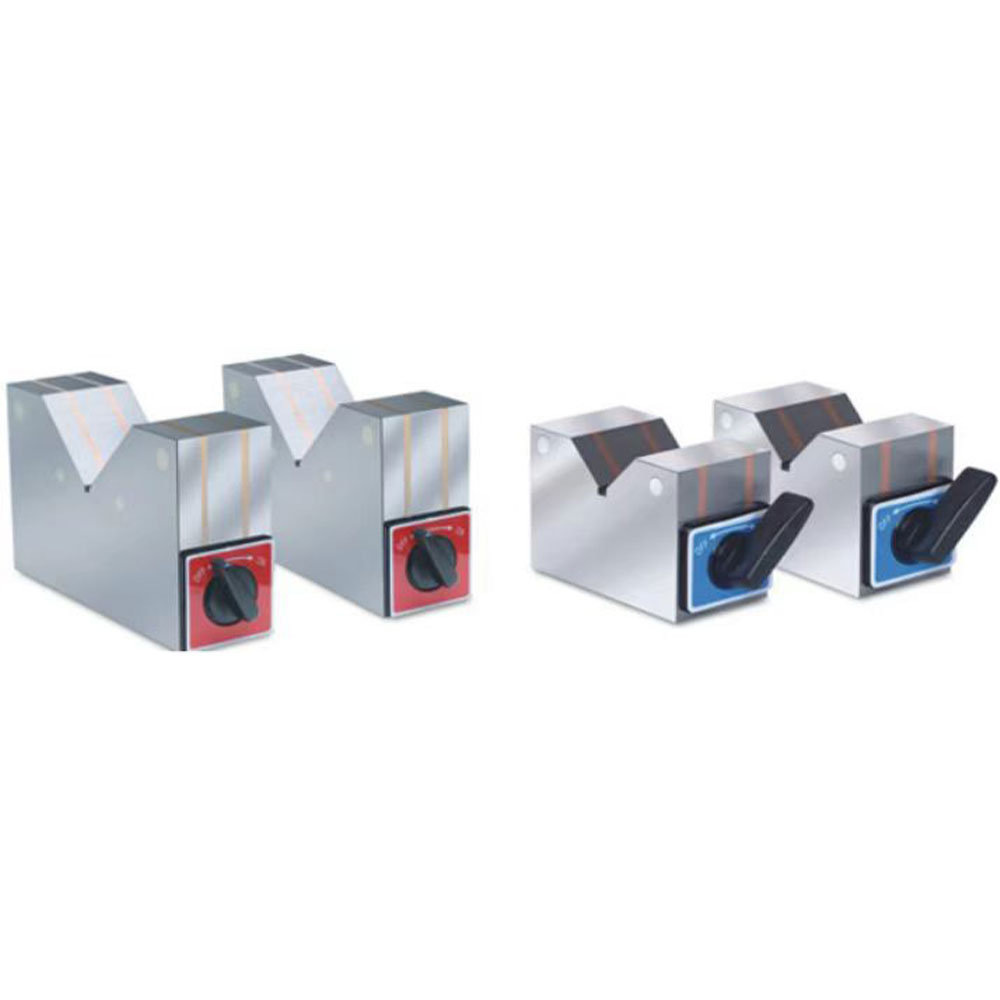

- Magnetic V-blocks

- Magnetically conductive blocks

- Hand-pushed iron removal vehicles

- News

- Contact Us

+86-574-65803327 / +86-574-65927988

+86-574-65803327 / +86-574-65927988 weihui@nbwhcy.com

weihui@nbwhcy.com

Español

Español 简体中文

简体中文